BASIC CARDING ACTIONS

Basically, there are two action in carding machine first , one is carding action (which take place between flats and main cylinder of carding machine) and the second one is the stripping action (which take place between Taker-in and the main cylinder of the carding machine ).

Carding action :

In this action the fiber separation process from the fiber tuft is carried out. By held the in between the two wire surface . Now the required condition to carry out carding action are following :-

1. The first condition is that there should be always two wire surface facing each other and they should have the minimum distance of 0.3mm in between them.

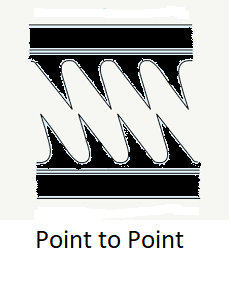

2. The second condition is that there is always point to point facing in between those two wired surface.

3. The third condition is that the interacting surface should move in same direction or in opposite direction. if there are moving in same direction then the charged surface should have to move at higher linear velocity.

Stripping action :

In this action the fiber transfer process from one wire surface to other . The necessary condition for stripping actions of fibers are following :-

1. The first condition is that there should be always two wire surface facing each other and they should have minimum distance of 0.3mmin between them.

2. The second condition is that there is always point to back facing in between those two wired surface.

3. The third condition is that the interacting surface should move in same

direction or in opposite direction. if there are moving in same

direction then the charged surface should have to move at higher linear

velocity.

Theories of Carding Machine :-

There are three carding theories which are following :-

1. Classical theory

2. Strang's theory

3. Kaufman 's theory

1. Carding theory :

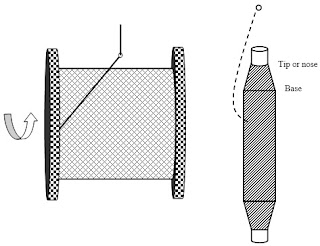

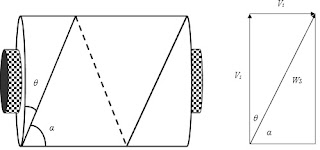

The basic carding and stripping action is know as the carding theory and these action are discussed above in the topic (basic carding action ) . This theory state that the fiber are carded in between two oppositely inclined wire surface moving at a speed and there is some inclination between the wired points which causes the sliding of the components of fiber tension acting, on the fiber is strong enough to move the fiber down to the wire base. There are some drawback in this theory that is does not take the centrifugal force and the presence of the air current due to rotating elements . The carding force which presses the fibers toward the base of the wire is too small in comparison to components of fiber tufts between the working surface and centrifugal force acting on the fiber tuft.

2. Strang's theory :

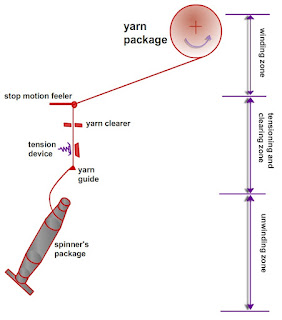

In this theory of carding machine is also know as boundary layer theory. This theory state that in the card the cylinder is considered to be enclosed from all the sides by flats , back and front plate , licker-in , doffer and cylinder under ceasing and rotate in medium of still air .basically this theory tell that the series of concentric layers of air surround the cylinder and rotates along with it with different velocities.

The major drawback of this theory is that it is in applicable in explaining the fiber transfer from licker-in to cylinder strang's theory is explaining the carding action in very unrealistic way .

3. Kaufman's theory :

This theory state that as we introduce the fiber tuft into the narrow gap in between the cylinder and flats the fiber tuft get compression force into the wire clothing of both flats and cylinder . Since the flats are stationary as compared to the fast moving cylinder . According to Kaufman calculation the compression force against the cylinder acts six time lager than the surface area of flats . The penetration of wire points into the tuft is immediately followed by the shearing action on due the greater speed difference the tufts is pulled apart into pieces .