TEXTILE,YARN MANUFACTURING , FABRIC MANUFACTURING ,TEXTILE TESTING , TEXTILE PROCESSING ,TEXTILE DESIGNING ,GARMENT MANUFACTURING .

Opening Operation in Blowroom (Spinning )

As the raw material enters in the spinning mill in highly compressed form (Bale) . Raw material is made highly compressed to make the transport of the raw material easy and also to make storage easy. So, opening become the first basic operation of spinning.

As the raw material is highly compressed due to which it requires various type and degree of opening.

|

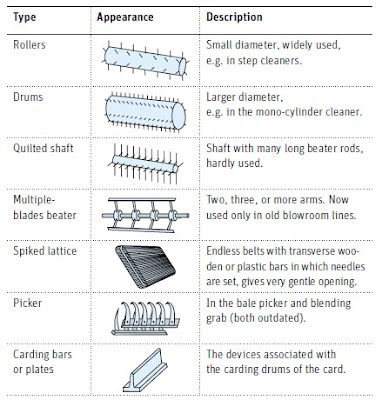

| Fig 1 (Opening Device) |

Opening devices

Machines used in short-staple fiber spinning and there operations

Staple fiber (i.e raw cotton, flax, Hemp, wool) that can be twisted to form yarn is called staple fiber and it can vary in length. Around 33 million tons approx. processed as staple fiber every year in the world annual fiber consumption. It become important to know about the technology which is required to convert the raw material to semi finished or fully finished product.

|

Operations |

Machine used |

|

Opening |

· Blow room machines · Card · Open end spinning machine |

|

Cleaning |

· Cleaning machine · Card · Comber · Draw frame (dust removal) · Rotor spinning machine |

|

Blending |

· Blowroom machine · Card (fiber blending) · Draw frame |

|

Aligning |

· Card · Comber · Draw frame · Roving frame · Final spinning machines |

|

Uniting |

· Card · Comber · Open end rotor spinning machine |

|

Equalizing |

· Card with leveller · Draw frame · Open end spinning machine |

|

Attenuating |

· Card · Draw frame · Roving frame · Final spinning machines |

|

Imparting Strength |

· Final spinning machines |

|

Winding |

· Roving frame · Final spinning machines |